本页未翻译。您正在浏览的是英文版本。

Due to legacy approaches and lack of standardization, the management of trustable technical specifications of photovoltaic components is an ongoing challenge in the solar industry. While the growth in PV has brought fast development of a variety of products to the market, it has also created a new problem: It’s becoming increasingly difficult for project developers to manage and accurately evaluate the technical specifications of the modules, inverters and other components of a PV power plant.

As the range and technical complexity of components grows larger, the inconsistencies in technical specifications and multiple versions or errors make it harder for industry stakeholders. Legacy approaches in the use of technical specifications and lack of validation tools are sources of inefficiencies and misunderstandings. In addition, the modern PV simulation software requires more rigorously defined and validated parameters to eliminate simulation errors.

Working with reliable data is essential at every stage of solar project development, but it is particularly critical for PV system performance simulations. PV system design has to be optimized to be economically viable under site-specific solar, weather and environmental conditions. Without a trustworthy database of PV modules, inverters and other technical components, PV simulations will fail to deliver reliable performance estimates during the project design phase.

Existing data specification formats and the way they are managed are a source of inefficiencies and misunderstandings. As a standard, PV module specifications are stored in PAN files, while inverter specifications are stored in OND files. Both formats are plain text files that anyone can open, modify, and freely share – potentially with altered and difficult-to-verify information. Multiple versions of technical specifications often exist for the same product, which can be another source of confusion.

The unverified technical specifications may skew a project design and energy yield estimates. This study, for example, evaluated and compared yield estimates across various PV simulation models, revealing wide variation of errors and highlighting the strong dependence between the model performance and the specification of the PV technologies. The performance of components, alongside inaccuracies in solar radiation data, are reported as key sources of error.

Another research study pointed out that specific technology and materials used in PV cells and modules – such as polycrystalline vs. monocrystalline, anti-reflective coatings, etc. – significantly impact the energy yield. Certain technology combinations perform better in specific solar resource conditions, defined e.g. by spectral effects or diffuse light. The PV module technologies also respond differently to factors of weather and environment, such as air temperature, shading, albedo or wind.

Due to the complexity of component parameterization for PV simulation models, the specifications may project overly optimistic performance outcomes. Inaccurate data can mislead developers and investors, resulting in flawed designs and posing financial risks to the project's viability.

To mitigate these risks, the solar industry needs more rigorous management and stringent verification tools for technical specifications of PV components.

As new technologies emerge, the PV simulation tools must be continuously updated and validated to keep pace with innovation.

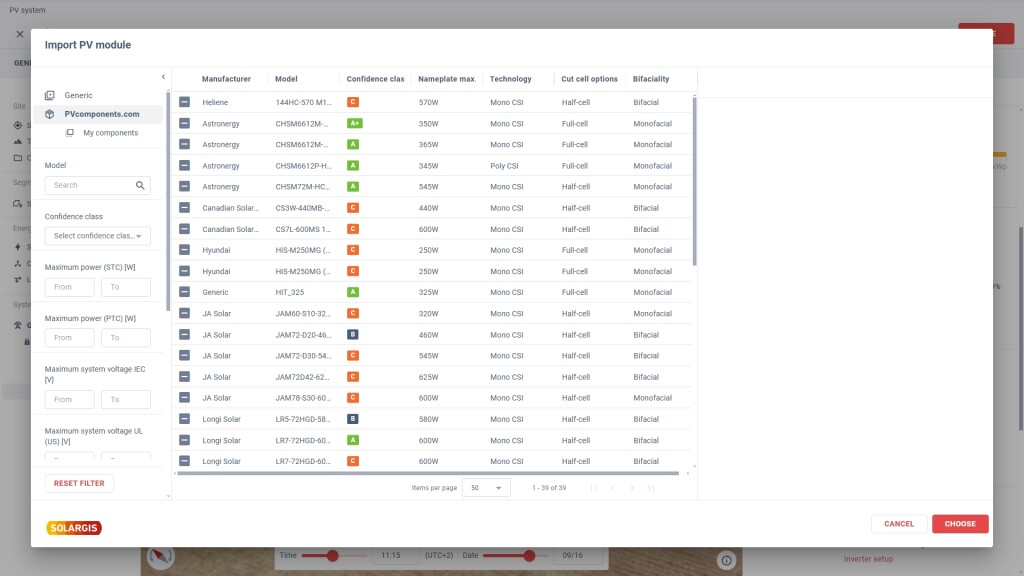

Solargis addresses this challenge with the new-generation Solargis Evaluate. The software is integrated with a new PV Components Catalog (PVCC) web-based platform, that is designed to become the market's most comprehensive and verified database of modules, inverters, and other PV technology. The components in the PVCC are verified through advanced models, algorithms, data, and expert validation – using a combination of automated and manual checks – to ensure that PV component specifications are to be trusted.

Verification process results in assigning a 'Component Confidence Class', a category indicating the reliability of the data describing the component. The component is assigned to the specific category based on criteria defined by automated validation tools and verification by authoritative experts. This simplifies the work of industry stakeholders, who only need to check the 'Component Confidence Class' in the PVCC. If a PV module or inverter are rated as Class A, or A+, they can be trusted by all stakeholders without further investigation.

PV Components Catalog integrated in Solargis Evaluate assigns a 'Component Confidence Class' to each PV component, indicating the reliability of the data.

Having access to reliable data benefits all industry stakeholders – manufacturers, certification authorities, PV developers, investors, auditors and the banks that approve the project financing.

By addressing the issue of unverified technical data for PV modules and inverters, and later also other technologies, Solargis Evaluate 2.0 enhances the accuracy of PV simulations, enabling solar developers to design projects that are realistic and financially viable.